1st TBM for Mumbai – Ahmedabad Bullet Train Passes Factory Tests

August 26, 2024 Update: Two images of the TBM have been removed from my post per Herrenknecht’s request.

August 20, 2024 Original Post: Say hello to TBM S-1392! Herrenknecht AG in China has completed factory acceptance tests (FAT) for the first tunnel boring machine (TBM) of the 508.17 km Mumbai – Ahmedabad High Speed Rail (MAHSR Bullet Train) project.

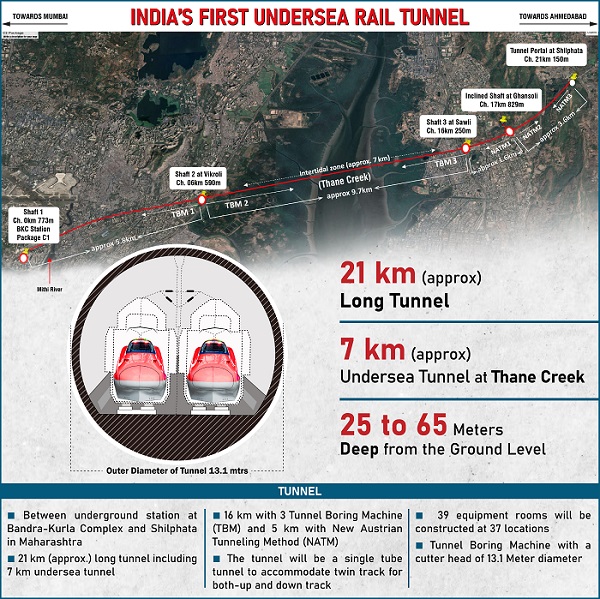

This 13.56m diameter mega TBM (largest in India) will be deployed by Afcons Infrastructure on the project’s 20.377 km underground Package C-2 between Km 0.773 (Bandra Kurla Complex Station) and Km 21.150 (Shilphata Ramp). This section includes a roughly 3 km “undersea” tunnel below Thane Creek.

This mixshield machine will be commissioned in 2025 along with another machine to construct a 16 km single-tube tunnel to accommodate both up-line & down-line tracks. As shared in 2023, although NHSRCL’s tender documents mandate at least 3 machines to be deployed, I hear Afcons will be starting out with 2 machines and order another if things start going awry.

India’s National High Speed Rail Corporation Ltd. (NHSRCL) had awarded Afcons Infrastructure with underground Package C-2’s Rs. 6397.27 crore contract in June 2023 with a 1888 day (5.17 years) deadline.

Afcons is currently constructing 3 shafts at BKC Station, Vikhroli, and Sawli at approximate depths of 36m, 56m and 39m respectively to launch and retrieve their TBMs. An inclined shaft of 42m at Ghansoli and tunnel portal at Shilphata will facilitate 5 km of NATM tunneling works.

Although S-1392 is the first TBM to get ready it’s not necessarily “TBM-1”, shown in the graphic below, which is slated to excavate from Vikhroli to BKC Station. Its exact launch location remains unknown to me.

NHSRCL’s July update shows the excavation progress made at all shafts at the start of the video:

At 13.56m, Afcons’ mega TBMs will be the largest diameter machines deployed in India – bigger than even the Mumbai Coastal Road Project‘s 12.19m diameter CRCHI slurry TBM Mavala (DZ636) which built two tunnels between 2021-2023.

For comparison, the diameter of TBMs deployed for metro tunnels in India have so far ranged between 6.45m to 6.68m. Many 10m diameter machines have been deployed for water projects in Andhra Pradesh and Madhya Pradesh.

To getter better idea of how massive this machine is, check out Herrenknecht’s employee walking on the bottom-right corner of this snap:

S-1392 will now be dismantled and get ready for shipment. Looking at all pending activities, I see tunneling work starting no sooner than Q3 2025. Some of those activities broadly include disassembly, shipment & delivery, shaft completion, lowering & assembly, and site acceptance tests.

It remains to be seen, but most likely the second machine will be S-1393. As always, nicknames for both machines are expected to be assigned right before tunneling begins.

For more updates, check out the High Speed Rail section or my Home Page! Sign up for free instant email notifications on new posts over here. Like this post? Get early-access to updates and support the site over here.

– TMRG

When TBM2 and TBM3 meet in the middle of Thane Creek will they be reversed out?

why is a German company is making TBMs in China don’t they have enough recourses in Europe

It’s about market demand, China is the biggest market for Herrenknecht, I believe most of their TBMs are deployed in China for many large scale projects with TBMs being more than 15m in diameter and largest being 17.5m, and even ours are refurbished TBMs that came from China like this case.

No, Europe have strict environment law/taxes. Due to which all german companies produces their goods outside of EU. Even Bosch, Mercedes, bmw etc. manufacturing plant setup outside of EU.

It is easy to manage supplying these heavy equipements in asia pacific region through an asian country only rather than europe which makes it convenient for both..the client and supplier..however the amount of tunneling going on in India I believe very soon Harrenknescht will have assembly unit in India like Terratec has one in Nagpur (if I am not wrong)

Its about cost. Cost of manufacturing is low in China as compared to Germany

I really liked your comparison…I ZOOMed in..Ha..ha

Germans pushing Obsolete technology in China and AFCON has joined the band wagon spending Bharat tax payers money in China. Bharat should stomp down on AFCON. Lazers technology AFCON managers management

What’s the expected completion date for the full length?