Afcons Begins Assembling 1st TBM for Mumbai – Ahmedabad Bullet Train in Ghansoli

Afcons Infrastructure last week received and started assembling parts of their first tunnel boring machine (TBM) in Navi Mumbai for the 508.17 km Mumbai – Ahmedabad High Speed Rail (MAHSR Bullet Train) project.

The mixshield TBM, most likely S-1392 which passed factory acceptance tests (FAT) in the summer of 2024, is currently being assembled at the project’s Shaft-3 site in Ghansoli’s Sawli neighborhood where a 39m deep circular shaft has been constructed.

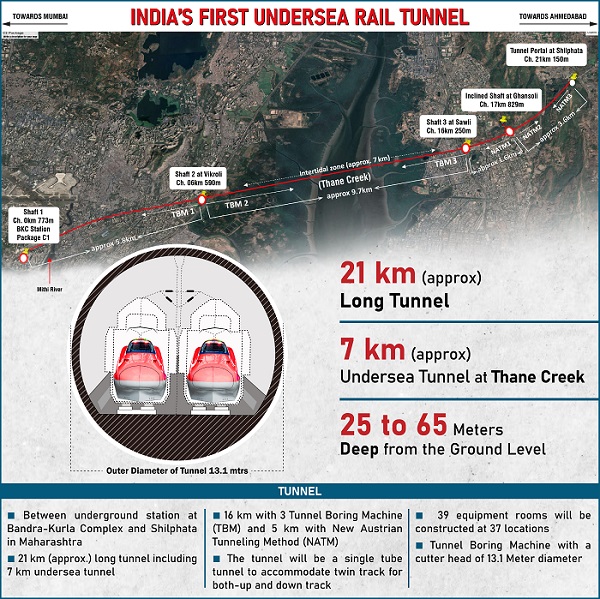

This shaft (view satellite imagery) will be used to facilitate tunneling works on the project’s 20.377 km underground Package C-2 between Km 0.773 (Bandra Kurla Complex Station) and Km 21.150 (Shilphata Ramp). This section includes a roughly 3 km “undersea” tunnel below Thane Creek.

Afcons’ TBM by Herrenknecht AG has a 13.56m diameter cutterhead which will make it the largest TBM to be deployed in India until larger Herrenknecht machines for Versova – Dahisar Coastal Road project in north Mumbai get going. It had been stuck in China for over a year due export restrictions in place by the Chinese government which I’ve explained in the past as it also affected Kanpur Metro Line-2’s tunneling plans.

With the machine now finally received, Afcons Infra will be looking to commission it as soon as possible. Their casting yard in Mahape (view satellite imagery) is packed and stacked with tunneling segments ready to be transported and fed to the TBM for tunnel ring building.

No dates or timelines have been announced by Afcons or NHSRCL, but I wouldn’t be surprised if assembly and site acceptance tests are wrapped up before the year ends.

This machine along with another machine to construct a 16 km single-tube tunnel to accommodate both up-line & down-line tracks. As shared in 2023, although NHSRCL’s tender documents mandate at least 3 machines to be deployed, I hear Afcons will be starting out with 2 machines and order another if things start going awry.

India’s National High Speed Rail Corporation Ltd. (NHSRCL) had awarded Afcons Infrastructure with underground Package C-2’s Rs. 6397.27 crore contract in June 2023 with a 1888 day (5.17 years) deadline.

Afcons has constructed 3 shafts at BKC Station, Vikhroli, and Sawli at approximate depths of 36m, 56m and 39m respectively to launch and retrieve their TBMs. An inclined shaft of 42m at Ghansoli and tunnel portal at Shilphata have been used to facilitate 5 km of NATM tunneling works.

From Sawli the machine will be commissioned towards Vikhroli (designated as “TBM 3” in the below graphic):

At 13.56m, Afcons’ mega TBMs will be the largest diameter machines deployed in India – bigger than even the Mumbai Coastal Road Project‘s 12.19m diameter CRCHI slurry TBM Mavala (DZ636) which built two tunnels between 2021-2023.

For comparison, the diameter of TBMs deployed for metro tunnels in India have so far ranged between 6.45m to 6.68m. Many 10m diameter machines have been deployed for water projects in Andhra Pradesh and Madhya Pradesh.

It remains to be seen, but most likely the second machine has been designated S-1393 and should be on its way over to India, if it hasn’t arrived already. If someone from the tunneling industry reading this knows its exact status then do leave a comment below.

For more updates, check out the High Speed Rail section or my Home Page! Sign up for free instant email notifications on new posts over here. Like this post? Get early-access to updates and support the site over here.

– TMRG

If tunneling starts at january 2026. What should be the approximate date of completion?

It depends on when the next machine arrives and what is afcons tunneling plan.

If they decide to use this machine for the entire 9.7 km streach till vikhroli (which would be the preferred option i believe ) and considering tunneling goes well then they may achieve about 300 m a month (which some companies have done) then it would mean completion in 3 years which would be splendid.

In that case we will see opening before 29 elections.

Just hope TBM 2 also arrives this week and tunnelling starts from both ends. 3 years completion would be fantastic. I believe afcons can do it like they did in kolkata under ganga metro (within 40 days).

That will most probably be the plan

It’s January, 2026 – how is the assembly going?

Why did Afcons defer buying the 3rd TBM ?

Want this lead to a longerand slower boring

What happens to the boring machine once the specific tunnel boring work is completed?

Can we not standardise on the tunnel diameter, so that the the same tunnel boring machine is used again and again, may be even in a different city. That would be cheaper and easier than getting it from China!

Its not practical to standardize a tbm size. It is like saying we will build a standard size house regardless of 1 person staying there or 10.

Metros use 6.5m because that is the most optimal size for them. Using bigger machines would make tunneling harder, more soil to be moved around, more tunneling segments per ring which all combined would increase the cost more than buying a new machine.

And it is not like tbms are not reused. India and china reuse a lot of their tbm’s. There have been machines used in 3 cities before being decommissioned.

Also, tbm sizes can be adjusted, for example the machines used for rrts project (which were larger than typical metro projects ) where downsized and redeployed. But adjustments like those are minor and easy to do.

Making a 6.5m machien converted to a 13m one would be very difficult and you also need to realize it is not all about the cutter head, a 6.5m machine is made to remove a certain amount of soil per day to move at optimal speed.

If you increase the cutter head diameter and do not upgrade the soil removing system (pumps, conveyer belts etc) then you are suddenly tunneling at a much slower speed.

The goal should be to make tbm in india and remove dependence from China.